- Surface milling on vertical and horizontal milling machines.

- Surface grinding parallel to milling table.

- Hole drilling on multiradial drilling machines.

- Threading.

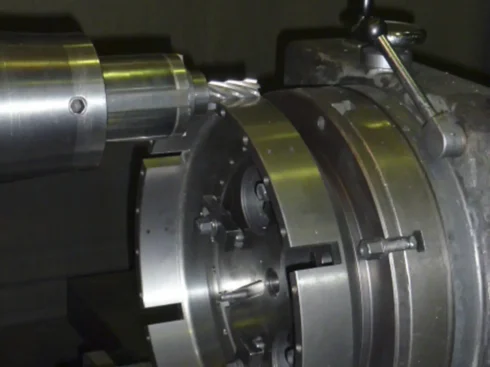

- Turning, boring and threading on numerical controlled machines and conventional boring machines.

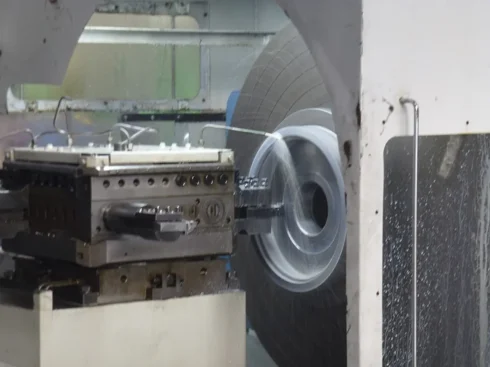

- Turning on vertical and horizontal lathes.

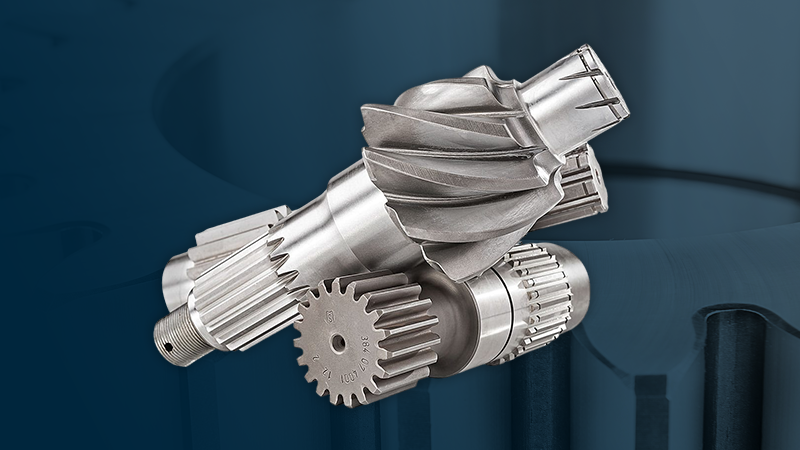

- Shaft grinding.

- Internal grinding.

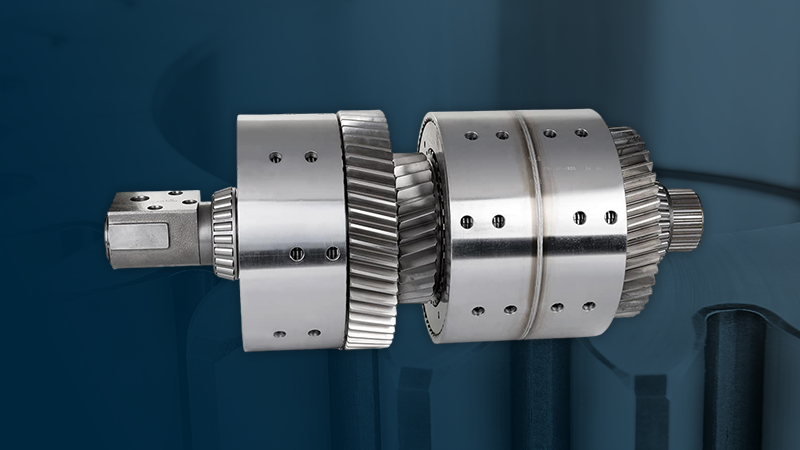

- Tooth grinding.

- Slotting.

- Broaching.

- Heat treatment.

- Washing and painting.

Endothermic carburizing with quenching or press quenching:

- PKMH chamber furnace of Elterma: dimensions of heating chamber:

900 mm x 820 mm x 1200 mm, - ALLCASE chamber furnace of Surface: dimensions of heating chamber:

900 mm x 850 mm x 1800 mm, - RDLEs-3 rotary-hearth furnace of Aichelin – batch max dimensions:

Ø 660 mm x 190 mm, - KSES 90/90 process line of Aichelin – batch max dimensions:

900 mm x 900 mm x 750 mm, - Quenching presses:

Gleason 36 D max = 840 mm, Gleason 537 D max. = 670 mm.

Induction hardening:

- AEG device for hardening of gears with diameter: D max. = 900 mm,

- FDF device for hardening of gears and shafts (power 600 kW frequency 8 kHz).

Toughening and volume hardening:

- soak, chamber bath furnaces,

- furnace capability of heath treatment of components with a max diameter 660 mm and a max length of 1200 mm.