Lathes and boring machines:

- conventional lathes: diameter max. 800 mm, length 1500 mm,

- OSN lathes: diameter max. 1000 mm, length 450 mm,

- turning lathes: diameter max. 1250 mm, length 550 mm,

- boring machines: diameter max. 700 mm, length 800 mm.

Grinding machines with rectangular table and vertical spindle axis:

- maximum dimension: 800 x 1800 x 600 mm.

Hole grinder:

- module tooth from 2 mm to 8 mm,

- outer diameter up to 400 mm.

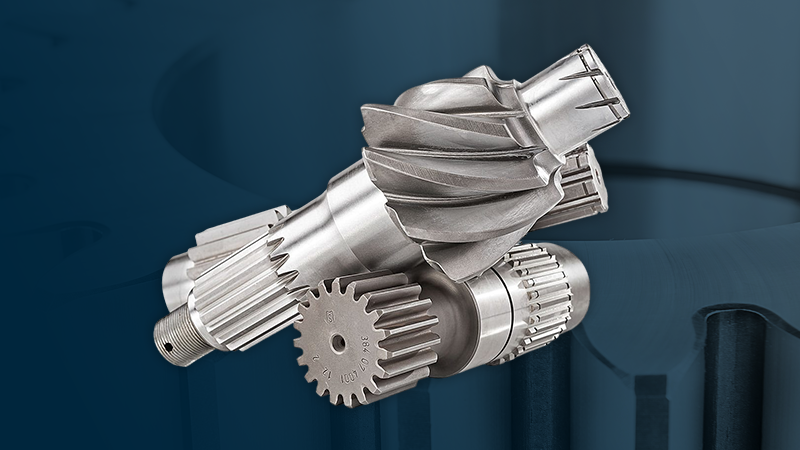

Generating machines for bevel gears with spiral teeth:

- Gleason method,

- tooth module from 4 mm up to 17 mm (face mills from 6” up to 18”),

- outer gear diameter up to 700 mm.

Hobbing machines for bevel gears with straight teeth:

- module tooth from 2 mm to 8 mm,

- outer diameter up to 400 mm.

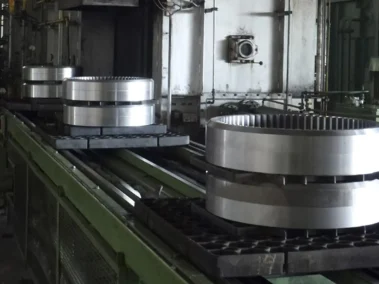

Gear hobbing machines:

- tooth module from 1,5 mm up to 16 mm,

- outer tooth diameter up to 1200 mm,

- face width max.: 1000 mm,

- hobbing accuracy class acc. to DIN 8,

- surface roughness max. Ra 2,5 ÷ 5.

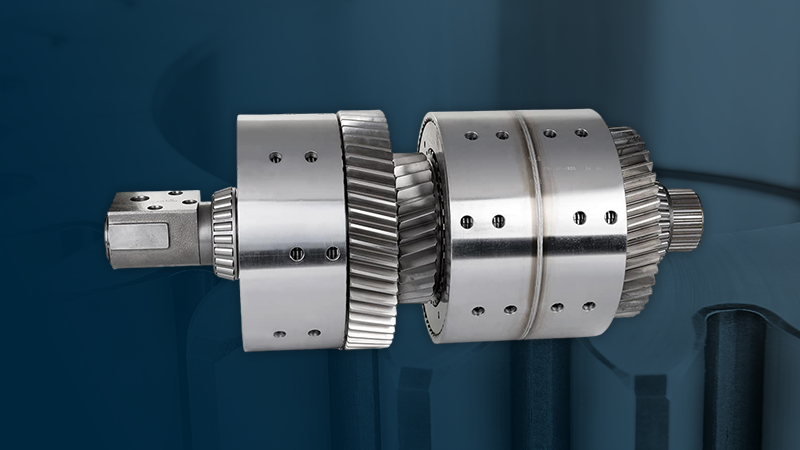

Hobbing machine for cylindrical gears with straight, helical and herringbone teeth:

- tooth module from 1,5 mm up to 14 mm,

- outer tooth diameter up to 900 mm,

- face width max.: 700 mm,

- finished tooth hobbing class acc. to DIN 8.

Straight teeth slotting machine:

- Fellow’s method,

- tooth module from 1 mm to 12 mm,

- outer diameter up to 800 mm,

- face width max.: 200 mm,

- gear class acc. to DIN 9,

- surface roughness max. Ra 2,5.

Machines:

Höfler Promat 400, Helix 400, Helix 700, Gleason PFAUTER P-800, Gleason PFAUTER P-600G:

- tooth module from 2,5 mm up to 12 mm,

- outer tooth diameter up to 960 mm,

- face width max.: 300 mm,

- finished tooth precision class acc. to DIN 7.